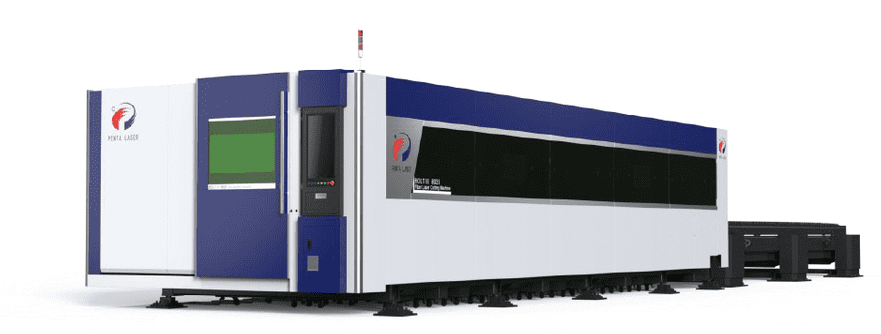

Overview

Bolt is a new model of PENTA LASER, a lot of new functions are integrated to improve various performances. It adopts a new CNC that reacts and moves in microseconds which allows to perform extremely advanced functions.

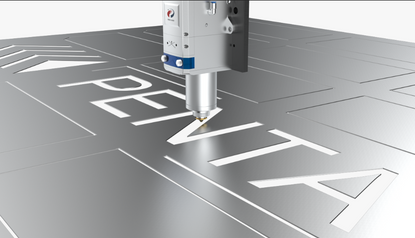

Bolt features very advanced features such as the maximum positioning speed of 200 m/min, quick start and stop, and maximum acceleration in 4G. Our Bolt special laser cutting machine is mainly used for the processing of Mild Steel, Stainless Steel, aluminum alloy, brass, copper, acid pickled plate, galvanized steel, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy and other plates with a length of no more than 3-12 meters and a width of no more than 1.5 to 2.5 meters with various thicknesses. Especially for large-format thick plates, it provides numerous advantages.

We independently developed the overall mechanical structure design with high dynamic response, took the lead in innovating the electric drive design, optimized, improved and redesigned the overall structure including key components such as bed and beam; based on the application of high-power laser, we designed the structure of the bed and the working table to improve the high stability of the high-power laser cutting machine.

Technological Innovation

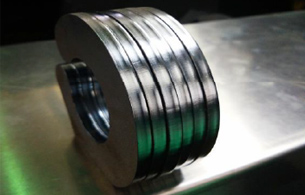

High power specialized cutting head, which can support durable and stable cutting. Unique cutting database for fast piercing, high speed cutting and thick plate cutting. The cutting capacity for stainless steel and aluminum is up to 50mm. Assembled with a new version of Smart Manager 5.0 CNC software, which is optimized for various piercing modes, and adopts the new generation of frog jump management which moves fluently without any pauses. The productivity on thin materials is boosted for more than 25%.; Metal obstructions can be detected to avoid collision to the uttermost during while cutting.

Intelligent Cutting Head

Equipped with a high-power special laser cutting head which supports the equipment to cut efficiently and stable for a long time to ensure the continuity of production for users. Automatic focus and fast perforation, its unique 360 degree anti-collision technology, bright surface cutting, sharp angle cutting and precision close space technology makes Bolt a precision machinery parts manufacturing tool.

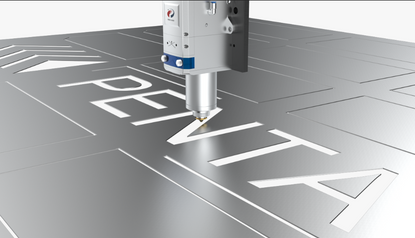

Cutting Samples

Operating System

SM 5.0 is equipped with Penta's cutting parameter database. The cutting parameters can be real-time adjusted during cutting, to achieve optimal quality. The software has various piercing parameters which can be set up to 25 layers.

SM 5.0 is also optimized for multiple piercing modes, e.g. continuous piercing, pulse piercing, blast piercing, etc. The frog jump management is upgraded with smoother motion and zero pause. With SM 5.0, thin plate production efficiency can be improved by over 25%. The system can provide auto gas shut-off during fast moving and more convenient auto edge detection.

BOLT 3015 Technical Specifications

| Cutting Area | 3000mm×1500mm |

|---|

| Mechanical Accuracy (VDI 3441) | ±0.03mm/m |

|---|

| Mechanical Repeatability | ±0.01mm |

|---|

| Rapid Speed | 200m/min |

|---|

| Maximum Acceleration | 4.0G |

|---|

| Laser Source Option | IPG/Raycus |

|---|

| Laser Power Option | 2000W-30000W |

|---|

| Cutting Ability Stainless Steel(Max.) | 1mm-100mm |

|---|

| Cutting Ability Mild Steel(Max.) | 1mm-80mm |

|---|

BOLT 4020 Technical Specifications

| Cutting Area | 4000mm×2000mm |

|---|

| Mechanical Accuracy (VDI 3441) | ±0.03mm/m |

|---|

| Mechanical Repeatability | ±0.01mm |

|---|

| Rapid Speed | 200m/min |

|---|

| Maximum Acceleration | 4.0G |

|---|

| Laser Source Option | IPG/Raycus |

|---|

| Laser Power Option | 2000W-30000W |

|---|

| Cutting Ability Stainless Steel(Max.) | 1mm-100mm |

|---|

| Cutting Ability Mild Steel(Max.) | 1mm-80mm |

|---|

BOLT 6020 Technical Specifications

| Cutting Area | 6000mm×2000mm |

|---|

| Mechanical Accuracy (VDI 3441) | ±0.03mm/m |

|---|

| Mechanical Repeatability | ±0.01mm |

|---|

| Rapid Speed | 200m/min |

|---|

| Maximum Acceleration | 4.0G |

|---|

| Laser Source Option | IPG/Raycus |

|---|

| Laser Power Option | 2000W-30000W |

|---|

| Cutting Ability Stainless Steel(Max.) | 1mm-100mm |

|---|

| Cutting Ability Mild Steel(Max.) | 1mm-80mm |

|---|