Spherical cellulose beads derived from wood pulp

Expected as alternatives to micro plastics

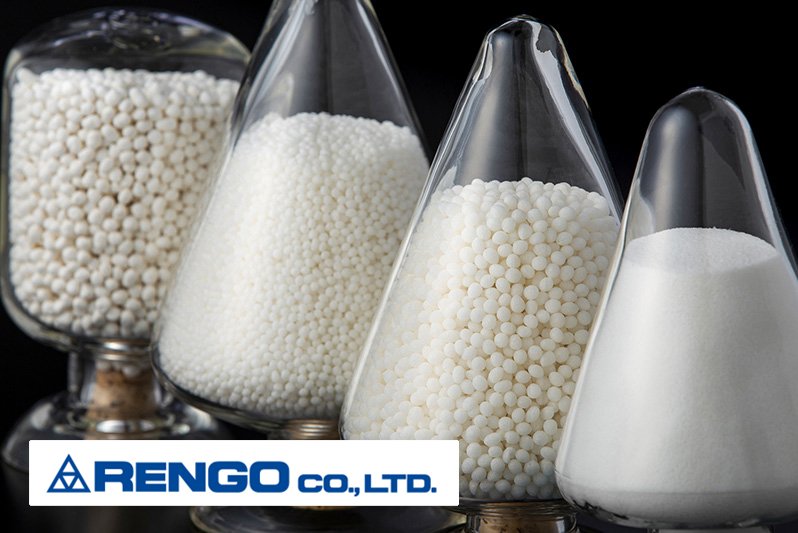

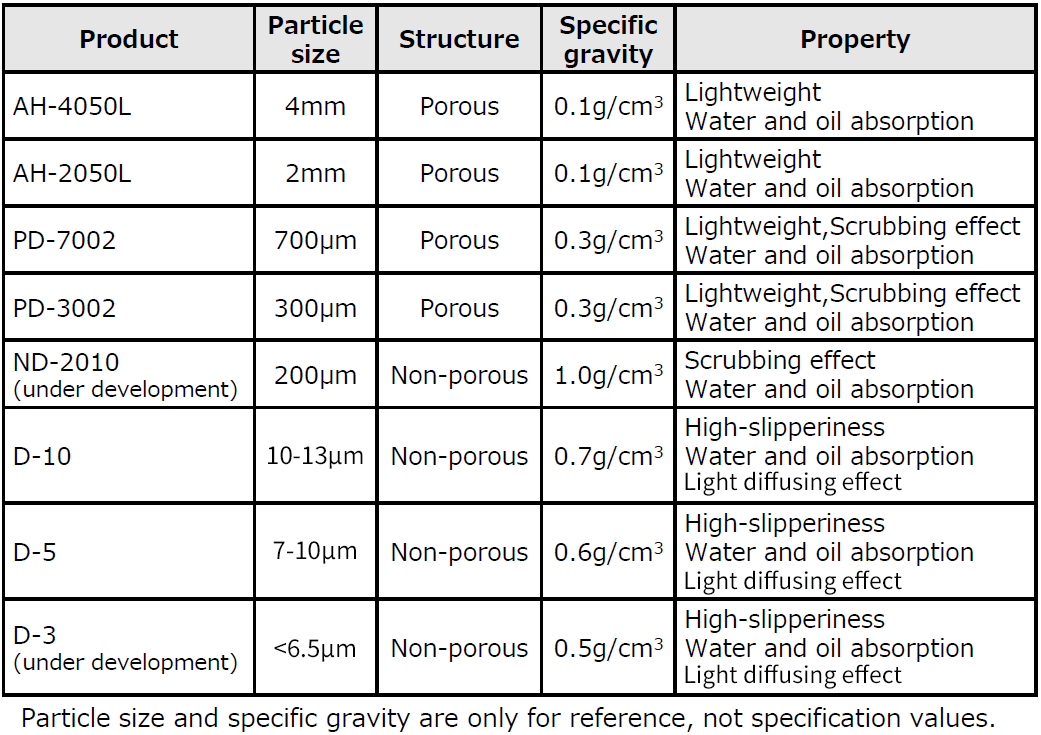

Viscopearl™ is a spherical cellulose bead made from wood pulp. This product is friendly to forest conservation, using FSC®-certified raw materials, offering a wide range of particle sizes from 3µm to 4mm. Biodegradable not only in soil but also in seawater, it is the most appropriate alternative for plastic microbeads.

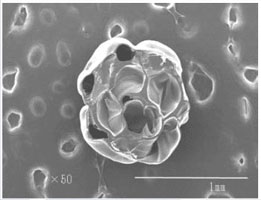

Diameter:10μm

Diameter :4mm

Diameter :700 μm

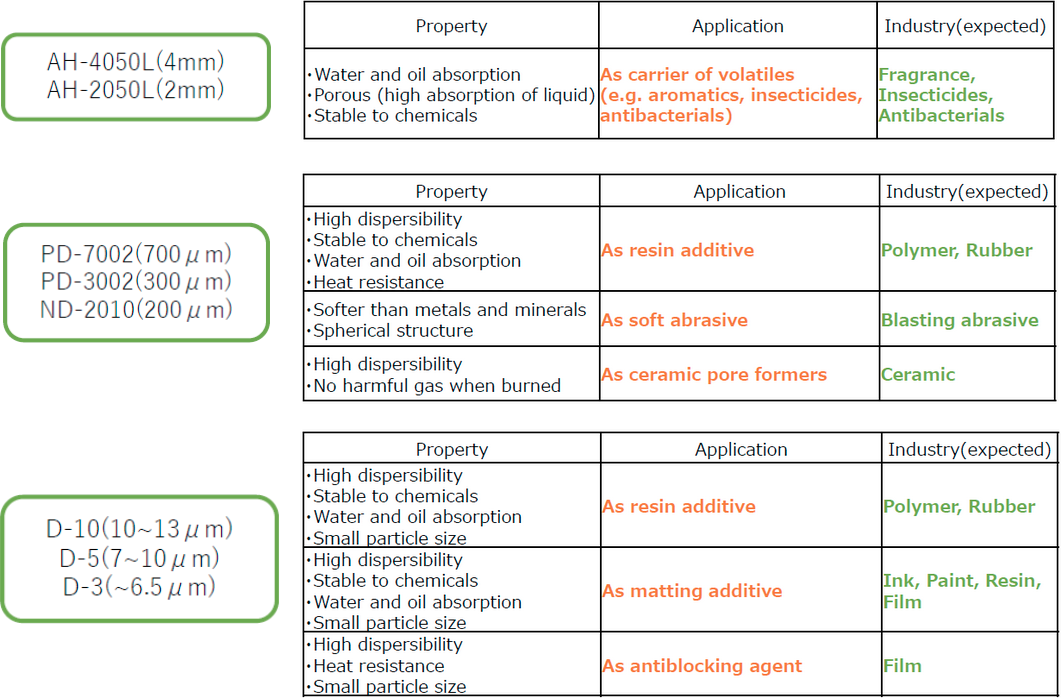

Viscopearl™ can be used as a carrier for aromatic agents or functional chemicals, raw material for cosmetics, or abrasive. It can also be used as a resin or rubber additive by using features of cellulose such as water absorbency. In addition, beads with particle sizes from 3μm to 10μm have a light diffusing effect, allowing them to be used as ink matting agents and light diffusing agents.

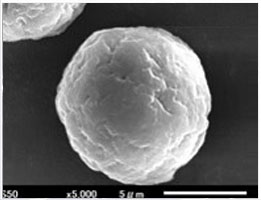

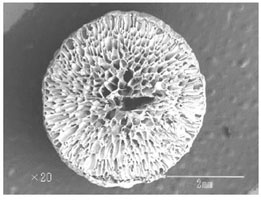

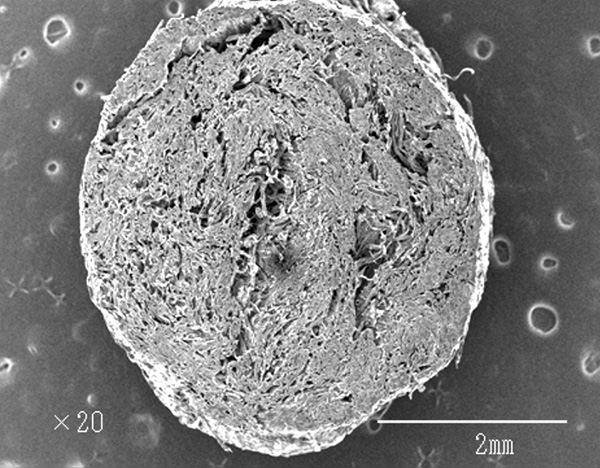

These are beads manufactured mechanically with wood pulp fiber as the main raw material. The inside of the bead is a continuous hole structure and the diameter of the pores is approximately 10μm. Besides use as a carrier for liquids, it can also be made a bead conjugated with powders such as activated carbon.

Appearance

Electron microscope photo

| Features of Viscopearl P |

|---|

| ・has a continuous hole structure |

| ・the diameter of the pores is approximately 10μm |

| ・Adjustable particle size: 2〜8㎜ |

| ・can be used as a carrier of liquids |

| ・can be conjugated with functional powders → make it easier to handle powdery materials. ※NOT biodegradability because of the binder |

| Conjugation technology |

|---|

It is possible to create compound beads by mixing with powders during the manufacturing process of Viscopearl P. By conjugating small particles with Viscopearl P, it makes handling easier without impairing functions as a powder.

|

Get in contact with our friendly support staff.

We will be happy to assist you in all matters of your purchasing requirements and are looking forward to your inquiry.

All fields are required.

Spherical cellulose beads derived from wood pulp Expected as alternatives to micro plastics

VIEW MORE DETAIL